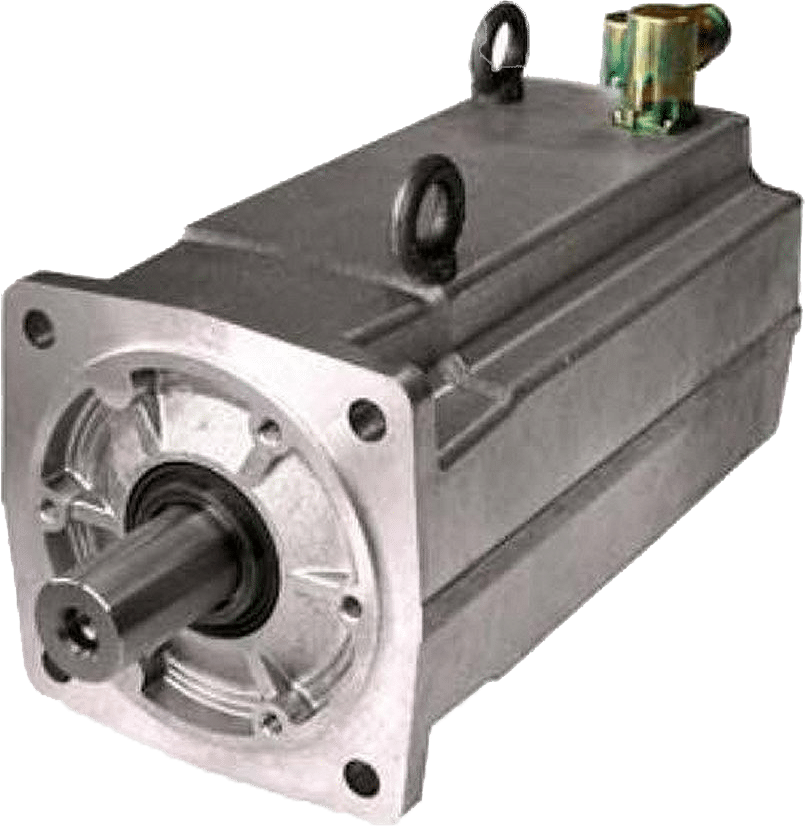

Technical data - Overview:

- Motor type: Permanent magnet synchronous servomotors

- Rotor design: Rare-earth magnet rotor with flux concentration

- Number of poles: 10

- Power range: 0.2 - 13.7 kW

- Torque range: 0.45 - 83 Nm

- Speed range: 0 - 9800 min-1

- Mounting: Flange with plain holes

- Mechanical interface: Smooth solid shaft (standard) / Keyed solid shaft (optional)

- Cooling: Natural convection / Forced ventilation (NX860V only) / Water-cooled (NX860W only)

- Degree of protection (IEC60034-5): IP64 (standard) / IP65 (optional) / IP44 (ventilated version)

- Speed/position sensor: Resolver / EnDat absolute encoder / Hiperface absolute encoder / Posivex (only with Digivex Motion)

- Other options: Brake / Thermal protection (PTC, Thermo switch or KTY)

- Certification: CE / UL

- Supply voltage: 230 / 400-480 VAC

- Temperature class (IEC60034-1) : CE - Class F / UL - Class A (NX1 - 2), Class F (NX3 - 8)

- Connections: Connectors / Cable outputs / Terminal boxes (NX860V)

Advantages :

- Precision and movement quality

- High dynamic performance

- Ruggedly compact

- Numerous options and customization capabilities

- Available in CE and UL versions

Applications :

- Machine tools

- Packaging machines

- Robot applications

- Special machines